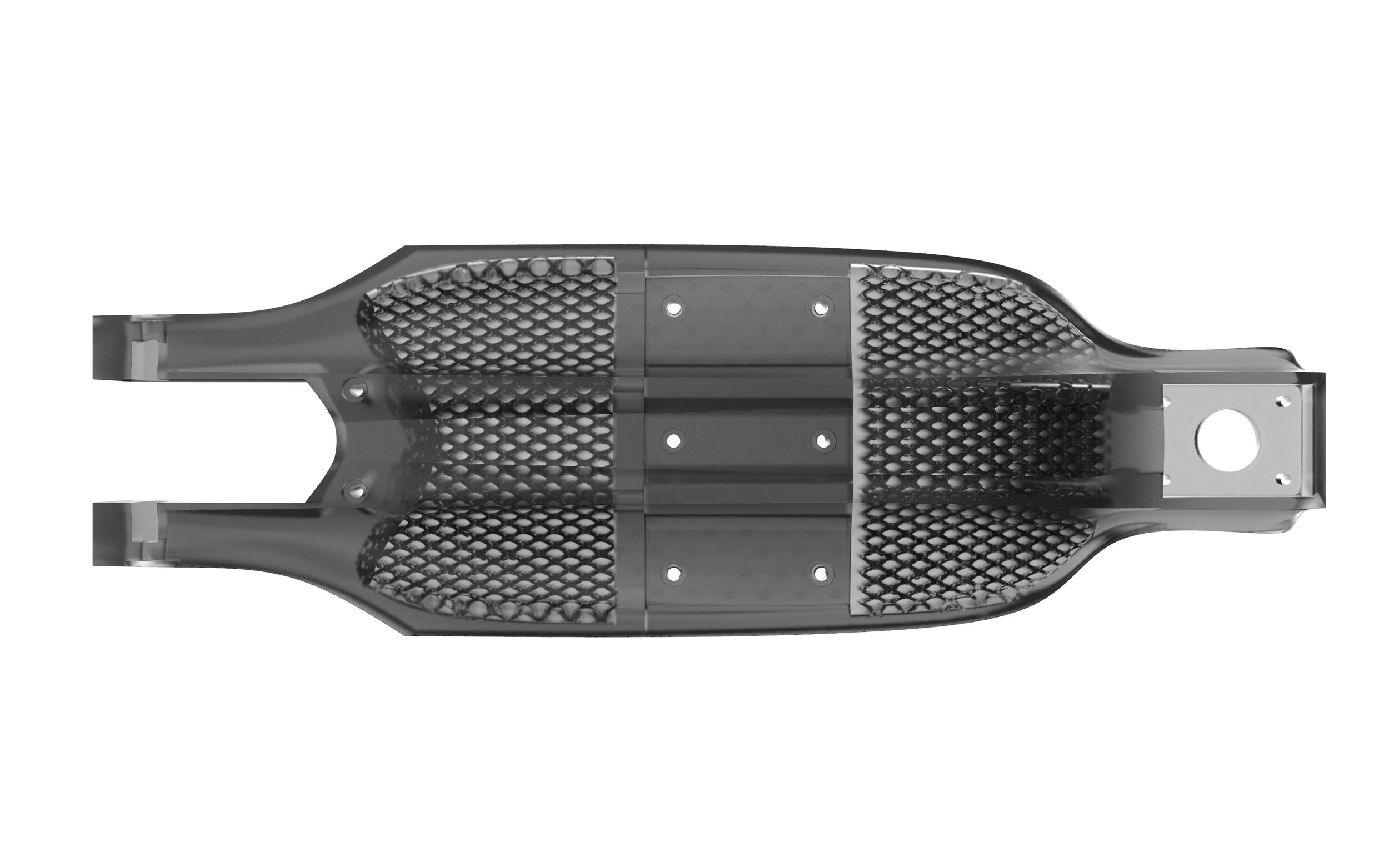

BULL RIDER SCOOTER

This scooter project was dreamed up as a material case study for Stratasys and Henkel to see what a soon-to-be-launched material was capable of, and to demonstrate just how easy Dura56 is to print on the Origin One. In just 81 days, we went from initial brainstorming, through three iterations, and then successfully created a finished product. All 3D printed parts, which consist of over 90% of the scooter’s mass, were printed in under 48 hours using 3 printers. Developed specifically for Origin® 3D printers, Dura56 is a durable, impact-resistant photopolymer with an exceptional surface finish and a low cost per kg. Weight reduction and FEA testing were done to inform the exterior shell geometry and the internal lattice systems. The major challenge was designing all 7 unique parts in parallel with sourcing existing hardware that would work to complete the overall scooter. Print orientation and strategic drainage holes proved to be very critical in the success and execution of this project in the short schedule it needed to be completed. Additionally, the deck being larger than the print volume made for some challenges in the assembly that were resolved with 3 structural slots & struts that were secured with barrel bolts.